Machine Installation: Where to Start

NOTE: ELECTRICITY IS VERY DANGEROUS. PLEASE USE A CERTIFIED ELECTRICIAN WHEN INSTALLING EITHER YOUR SINGLE OR THREE PHASE ICE CREAM MACHINE.

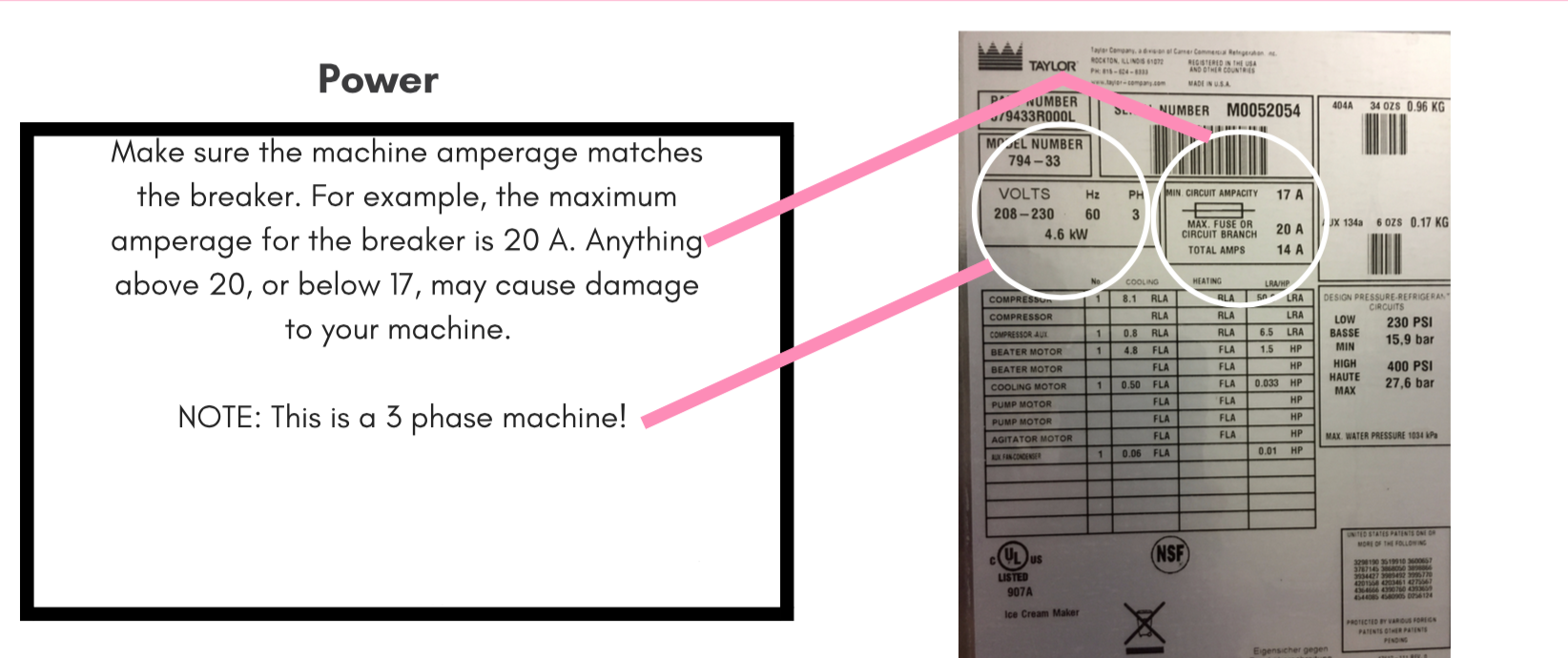

Three Phase Installation Polarity

Let's get started on how to install your machine, whether its a Taylor ice cream machine, a Taylor margarita machine, a Stoelting frozen yogurt machine or soft serve machine, here at Slices Concession we're here to help you. When installing a three phase machine it's vital to verify correct polarity since there's a 50/50 chance of being incorrect. To do this, check the direction of the beater that goes into the machine that churns the product. You must make sure it goes in the direction recommended by the machines manufacturer.

Beater Motor

Water or Air Cooled

All ice cream machines, from batch freezers to soft-serve machines, work by transferring heat away from the ice cream mix and freezing it in the process. The transferred heat is removed from the machine by either a water or air based system.

Air Cooled Machines:

Air cooled machines need a good flow of air traveling over the condenser coils. To make sure you are getting proper air flow. The machine needs six inches of space all around. Check the air flow path and see if your machine vents from the top or the bottom, if it is the bottom make sure the vent is pointed in a direction in which heat can travel away from the machine. We really want to be careful not to direct air from the hot vent back into the coils, this will severely hamper production and add strain to your components. If your vent is on top of the machine, the heat should naturally vent away on its own. Keep the room below 80°F for optimal efficiency.

ProTip: If you have multiple air cooled frozen dessert machines in a single room, extra A/C may be required to keep the equipment running at an optimal range. Another option depending on your setup may be to vent heat from the machines outside.

Water Cooled Machines:

Water cooled machines are hooked up to the COLD water line. Input for water is always at the water valve (pictured above). The other hose is connected to a floor drain. Colder incoming water will produce more ice cream faster. Water cooled machines need water pressure to always be ON, inside the machine there is a water valve to control how much water flows down the drain, your machine is tuned for optimal freezing / water savings.

ProTip: Water cooled machines can be hooked up to a Glycol tower chiller which cool and recirculate the water (Glycol) back into your machines. These machines make more practical sense when you are running many water cooled machines. We do have these chillers available if you would like to add one to your project.

Adjusting the Viscosity of Your Machine

"Over freezing your product is very bad for the machine, if you over freeze the product you could cause damage to the gearbox, beaters, or barrel of the machine. Please be extra careful to start adjustments warm and slowly move to a colder setting so you do not over freeze the machine."- Joe Kearns, Co-Owner Slices Concession

For specific frozen dessert machine installation and operating procedures, please see our Support Page. Where we have compiled Taylor Company, Stoelting, and Carpigiani operating manuals for your convenience.