Shipping FAQs

Packaging & Crating

SHIPPING INSTRUCTIONS

All machines being shipped are crated and require shipping insurance. It is buyer’s responsibility to make sure machine is crated for shipping and insured with freight insurance. Should damage occur during shipping buyer will work with insurance and freight company to get reimburse. If it arrives without walls or damage to walls, please uncrate the machine before you sign the Bill of Lading. Note all damages on the BOL and please call 352-888-1107 before accepting delivery. If damage is too extensive, please reject delivery. If damage is minor, please accept delivery and write on BOL in big letters “Equipment damaged from shipping”. Machine also has a shock indicator on the outside of the box. If shock indicator is red or missing, please write on BOL in big letters “Shock indicator is red (or missing) indicating rough handling”. All hidden damages need to be reported within 24 hours.

If machine is on wheels, please either use a forklift to move machine off the pallet or build a ramp to roll machine off the pallet. Please do not thump machine down as this can cause refrigeration leaks and damages to the refrigeration system. Please never use the plastic dispensing door to move or lift the machine, as damages to dispensing doors will not be covered under warranty. Machines that are tabletops need to always be lifted from the bottom.

We take the time to carefully craft a container by hand to ensure that your commercial ice cream equipment arrives to your business in perfect condition. We bolt the wheels to the wooden crate and use straps to tightly secure it to the container's bottom. We then add a wooden encasement around the machine to protect it from damage. Since this process is necessary to ensure your product's condition, we have a fee of $225 per machine.

Shipping The Machines Directly To You

Though the cost of shipping will vary depending on the location of your business, we assure you that our shipper has a wealth of experience in giving our customers the best carrier for the best price.

We recommend that the shipping address you give us be based in a commercial area rather than a residential property because it will help you save money. Also, depending on the carrier, lift gate for delivery may be an additional charge.

Protecting Your Investment With Insurance

We highly recommend investing in insurance to protect your machine(s) as they go through the shipping process. As a courtesy and thank you, we add shockwatch technology to each & every crate:

This shockwatch label, added to the outside of the container, changes it's label to red if there is any significant impact or violent movement incurred by the package. If you receive your container and the label is red please make a note of it on the bill of lading. This is one of the many ways we try to protect your investment.

Uncrating And Installation

We recommend you use a crowbar to unpack your machine

- Pry up the wood around the wheels and unstrap your machine.

- When lowering the machine off of the pallet it is highly recommended to be gentle and use a ramp (Jolts and rough handling can cause refrigeration leaks).

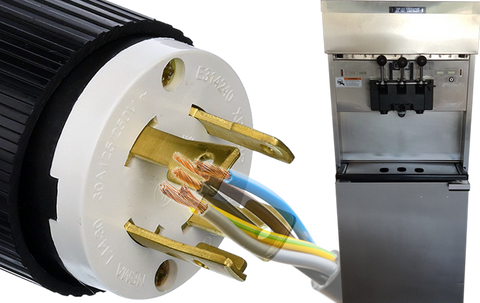

For installation & operation of your new machine we created a machine installation page where we walk you through:

- Checking your machine's polarity (specific for three phase machines)

- Properly connecting your machine's cooling system (air cooled & water cooled)

- How to adjust the viscosity of your machine, which affects your product's appearance, temperature, thickness and firmness. This is important because different machines require different viscosity settings.

- For The Machine Installation Page Click Here -